Lime oil & juice

Practical Action

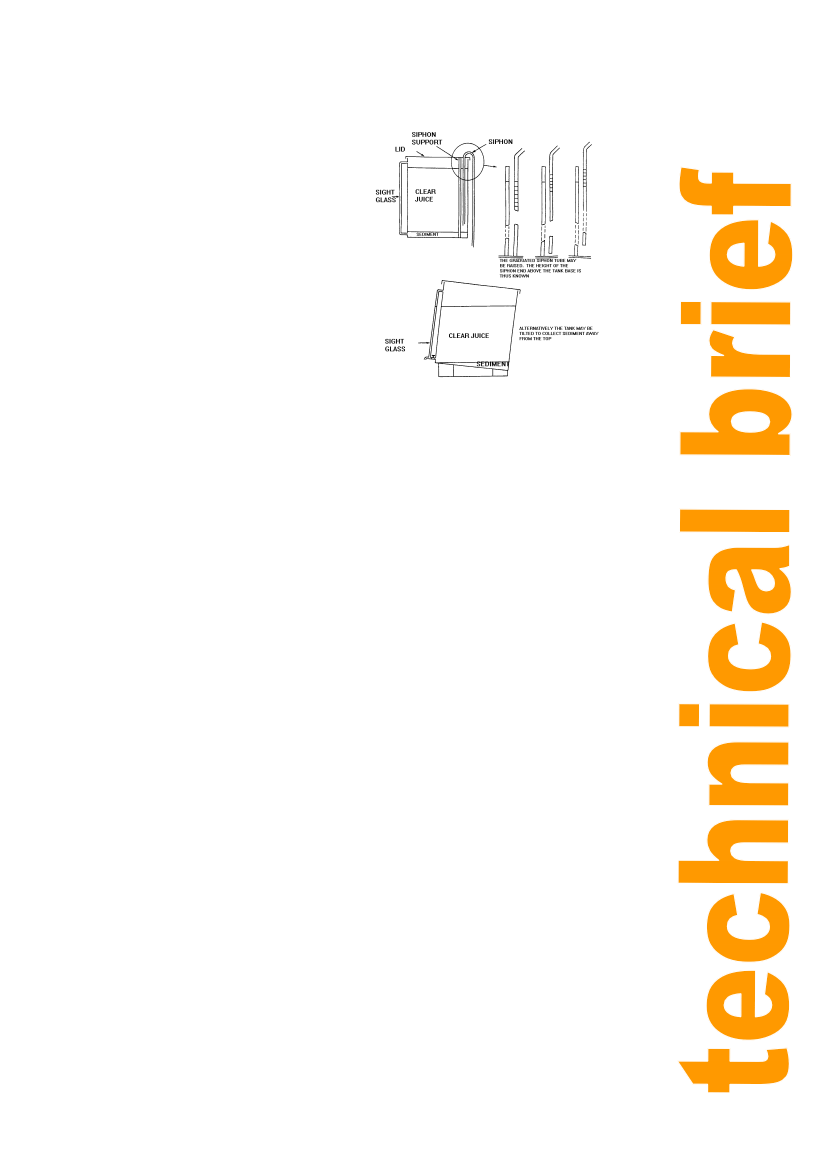

A multi-tubular stainless steel condenser of

the type shown (Figure 1) is the most

efficient, providing sufficient water

pressure is available.

It is essential that you have an efficient

Florentine flask oil separator. The glass

Florentine flask (it can be sealed up of

course) is useful for seeing what is

happening, but they do tend to get broken.

A single stainless steel Florentine flask of

the type shown in the still diagram should

be adequate for most needs (Figure 2).

The darkened areas in the still diagram

should be efficiently lagged in order to cut

down heat losses.

Figure 2: Florentine flask

The steam outlet holes in the open coil are generally arranged so that the steam is admitted

slightly downward and towards the centre of the still.

Lime oil storage

Lime oil may be stored in tanks (stainless steel or glass) and shipped in clear tinplate cans or

new metal drums (coated with a lining non-reactive to the oil, such as an epoxy resin). Lime

oil deteriorates during extended storage and so should be dispatched to the customer as soon

as possible after production.

Containers should be as full as possible to cut down oxidation and securely sealed; the oil

should be kept in a cool place and protected from sunlight. Both oil and juice may be

marketed through essential oil and commodity dealers, but samples must be provided to

them that are representative of the production.

5